In order to ensure the quality of the ice produced by your commercial ice machine, it is important to regularly clean, descale, and disinfect various components in an ice maker, including the machine’s housing, condenser, water filter, and exterior.

When using cleaning and disinfection agents, you should wear rubber gloves and protective eyewear, and consider wearing a face shield for added safety.

Here’s a simple breakdown of the cleaning and disassembly procedures for an ice machine used in your business:

Cleaning Procedure

- When the ice collection process is complete, and the ice has fallen from the evaporator tray, turn the ice maker’s function switch to the “Off” position.

- Remove the ice from the storage bin.

- Turn the switch to the “Clean” position to initiate the cleaning or disinfection process, allowing water to flow into the water tank.

- As the water pump operates, water flows through the distribution pipe and passes through the evaporator tray, adding an appropriate amount of cleaning agent to the water tank.

- The ice machine will automatically complete the cleaning process and then proceed to rinse the machine.

- Once cleaning is finished, the ice machine will enter a standby mode. At this point, switch the function to the “Ice Making” position to resume ice production.

Disassembling Components for Cleaning (or Disinfection) Procedure

- Turn off the water supply to the ice machine and disconnect the machine’s power source.

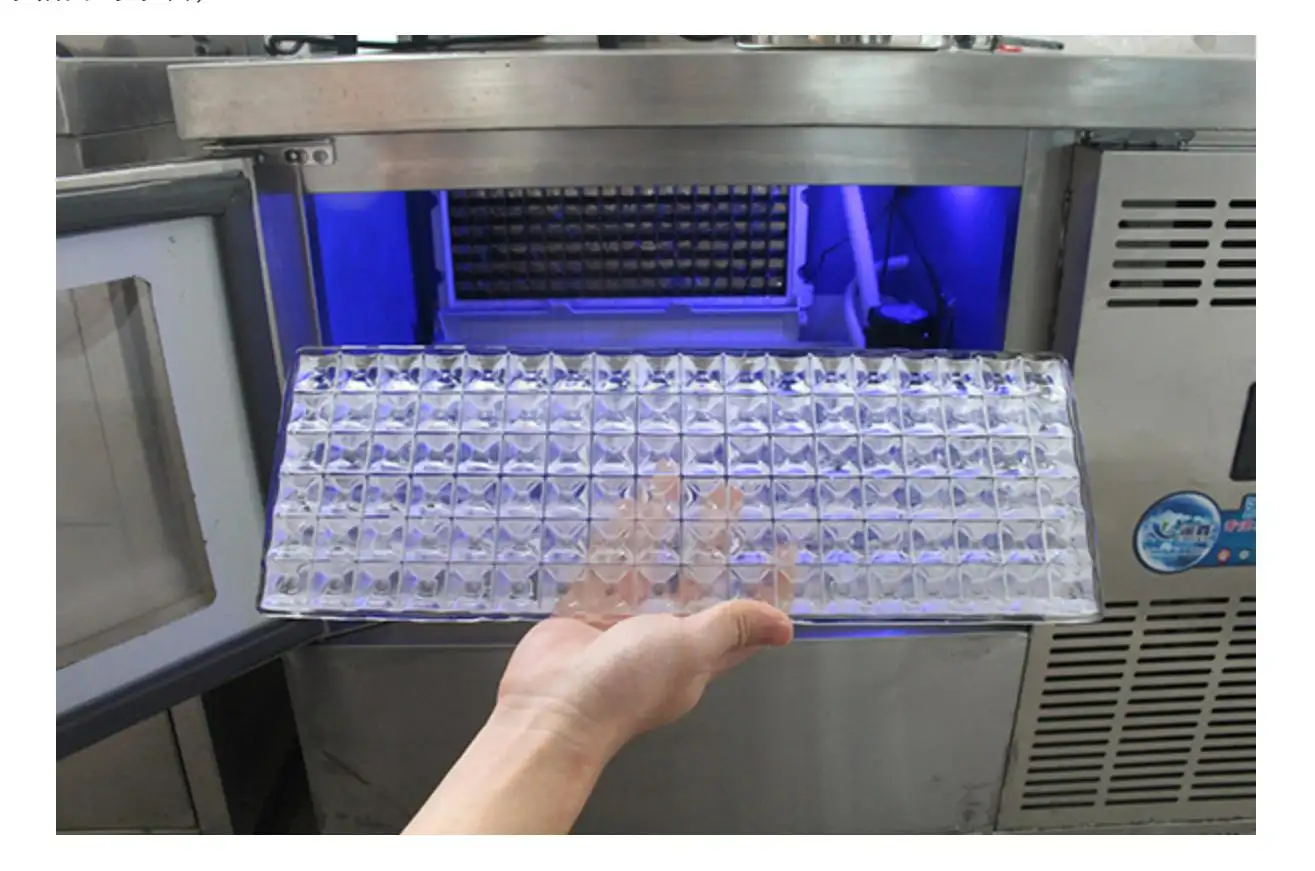

- Remove the components that need cleaning (or disinfection), such as the water curtain, distribution pipe, etc.

- Only use approved cleaning and disinfection agents.

- Cleaning and disinfection should be performed separately, with cleaning done before disinfection. Do not mix cleaning and disinfection agents.

- Once the cleaning or disinfection agent is added, do not interrupt the process manually, as this may result in residues of the agent inside the machine.

- Use the cleaning agent and a brush to clean the top, sides, and bottom of the protruding parts of the evaporator.

- Clean the ice machine’s filter: Soak the filter in a neutral cleaning solution, clean it with a soft brush, and let it dry before reinstallation. The exterior should be wiped with a cloth dipped in a neutral cleaning solution every three months. For the water system, follow the instructions in the “Cleaning Procedure,” performing disassembly and cleaning every six months.

- Finally, thoroughly rinse all cleaned (or disinfected) components with clean water, reinstall the removed parts, and then turn on the water supply and power source.

By following these cleaning and maintenance procedures, you can ensure the longevity and efficiency of your ice machine while maintaining the quality and purity of the ice it produces.